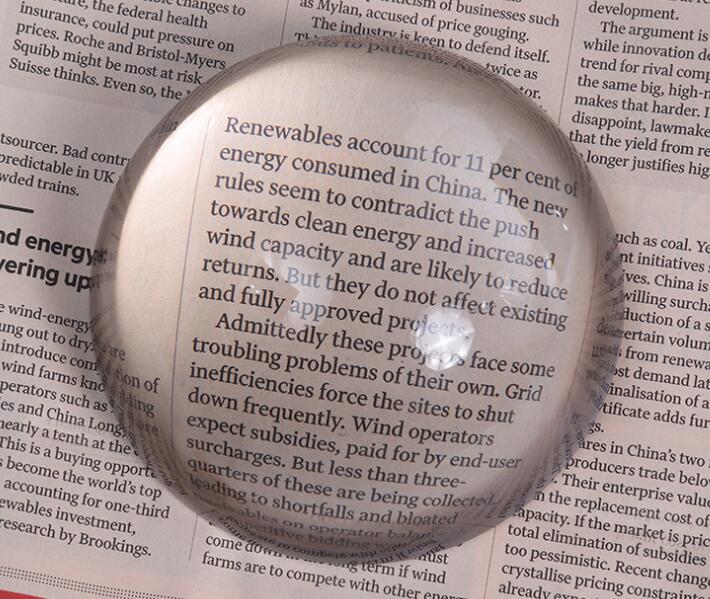

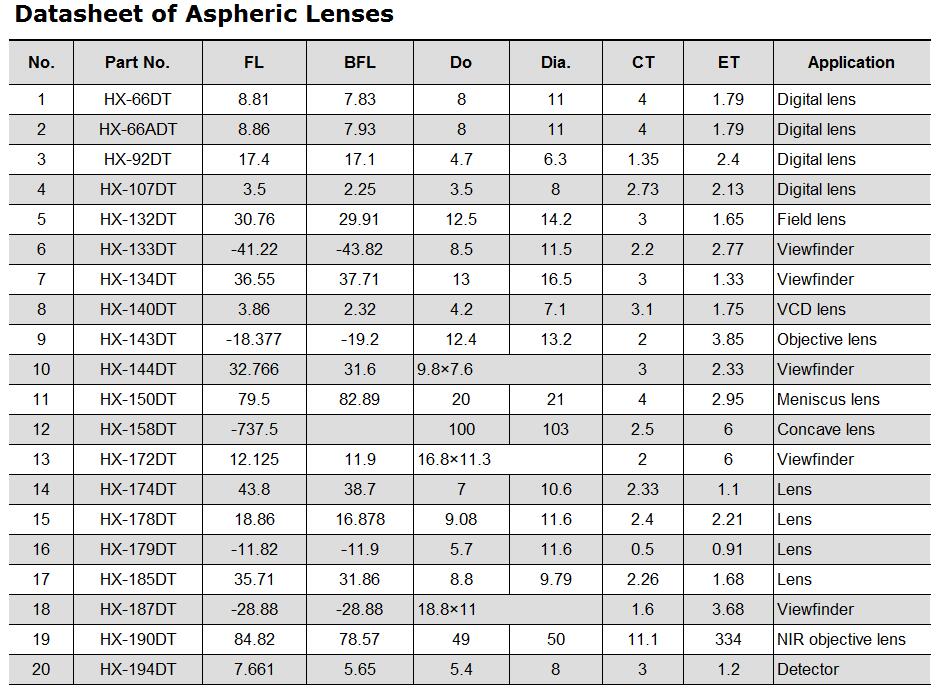

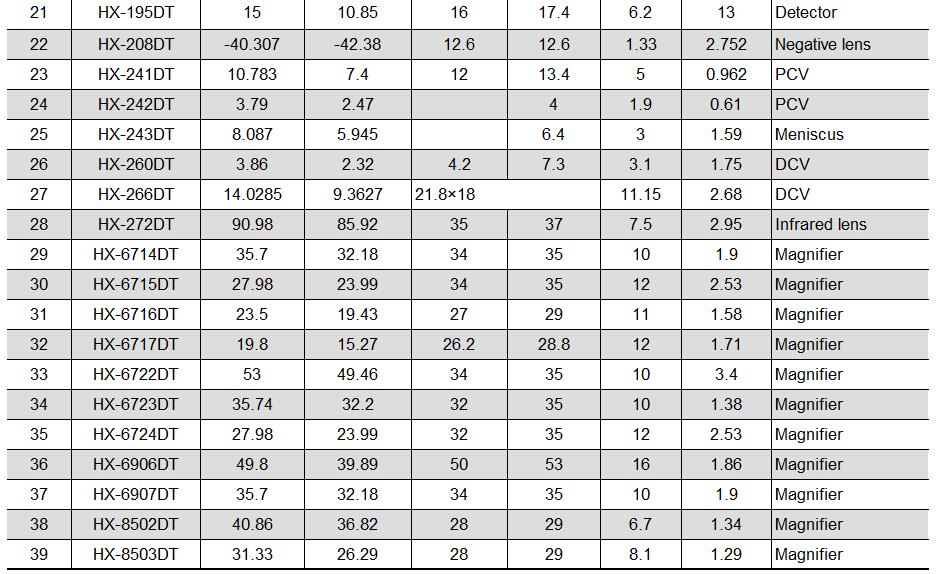

Our company is the first to apply aspheric lens in the design and production of magnifiers. Additionally it is applied in digital camera, VCD lens, video camera, camera viewfinder, telescope field lens and detector. Currently there are listed 40 kinds of aspheric lenses which are available now. Customers can choose them according to parameters listed. Also according to customer drawings, sample design. Our company can design and manufacture them according to supplied drawing and samples in order to meet the requirements of customs.

Aspheric lenses as the product of the latest photoelectric technology are often used to eliminate aberration and achromatic, reduce the number of lenses and their size. The optical plastic is suitable for making aspheric lenses because it has a good plasticity. Aspheric lenses made of resin have become more and more popular.

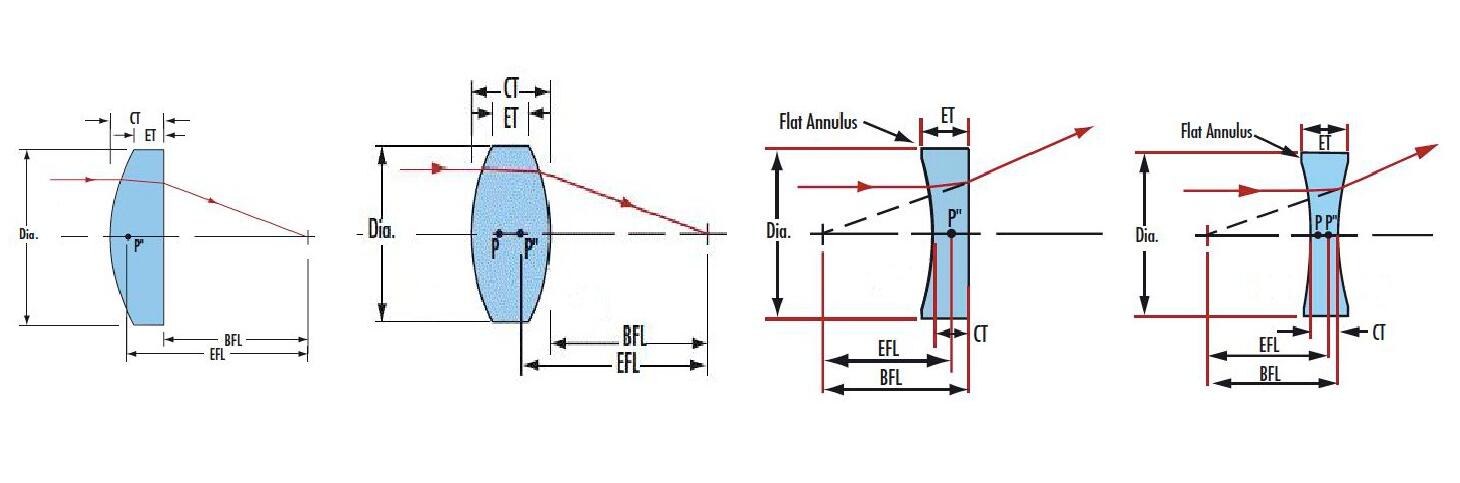

Dia.=diameter ; Do= Inside diameter ; FL= focal length

BFL= Back of focus ; CT= Center Thickness ; ET = Edge Thickness

Surface profile:

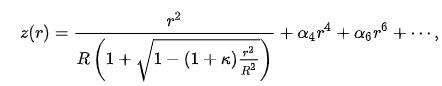

While in principle aspheric surfaces can take a wide variety of forms, aspheric lenses are often designed with surfaces of the form

where the optic axis is presumed to lie in the z direction, and z(r) is the sag—the z-component of the displacement of the surface from the vertex, at distance

r from the axis. The coefficients alpha;describe the deviation of the surface from the axially symmetric quadric surface specified by R and kappa .

If the coefficients alpha are all zero, then R is the radius of curvature and kappa is the conic constant, as measured at the vertex (where r=0). In this case, the surface has the form of a conic section rotated about the optic axis, with form determined by kappa :

The above equation suffers from strong correlation between the coefficients of the first term and the polynomial terms. This leads to strong divergences when it comes to fitting the equation to an aspheric surface. Therefore, different equations using "Q-polynomials" where coefficients are orthogonal to each other are an alternative that is sometimes used.