This specialized 3M adhesive tape is engineered for leading LED lens brands like CREE, OSRAM, Seoul Prolight, and Bridgelux. Engineered for technical precision, it delivers robust adhesion, thermal resistance, and application flexibility—ideal for commercial, industrial, and residential lighting projects.

This specialized 3M adhesive tape is engineered for leading LED lens brands like CREE, OSRAM, Seoul Prolight, and Bridgelux. Engineered for technical precision, it delivers robust adhesion, thermal resistance, and application flexibility—ideal for commercial, industrial, and residential lighting projects.

Key Features :

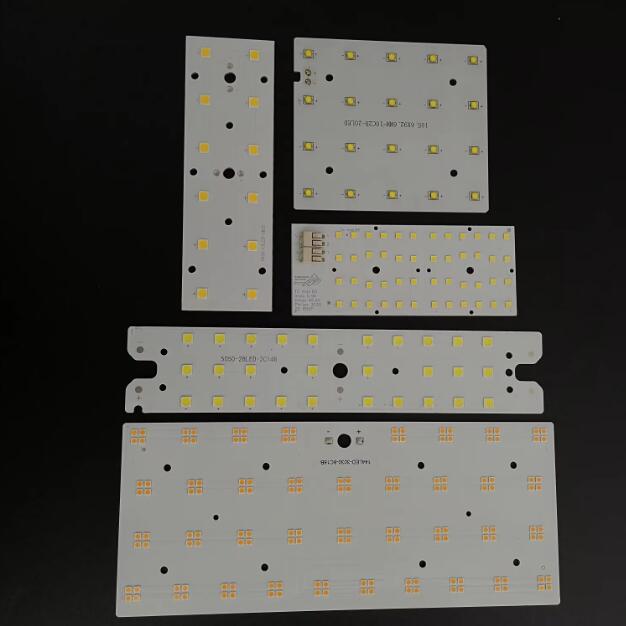

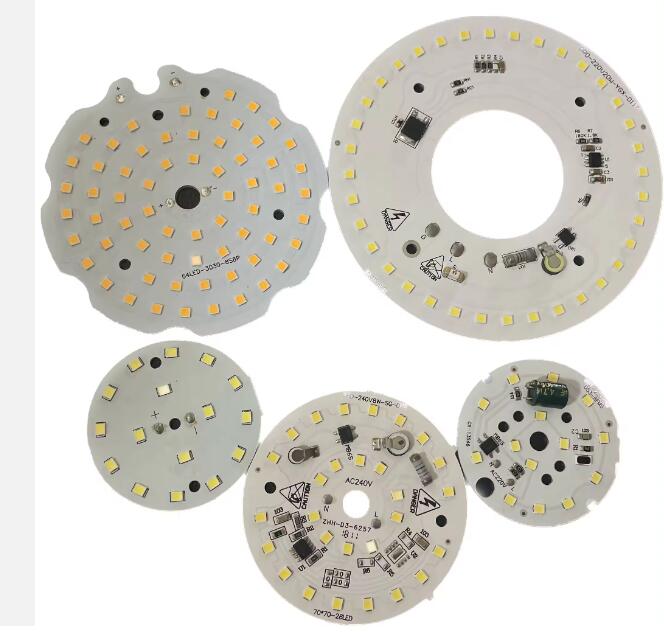

Leading Brand Compatibility: Perfectly tailored for CREE, OSRAM, Seoul Prolight, and Bridgelux lenses, solving mounting needs for COB and SMD LED modules.

Advanced 3M Technology: Offers high heat resistance (up to 150°C), preventing detachment in high-temperature environments and ensuring LED device thermal stability.

Customizable Design: Can be cut to specific sizes and shapes for round, rectangular, or specialty lenses, easing integration into lights, panels, and lighting accessories.

Installation Efficiency: 3M’s adhesive formula reduces setup time by eliminating the need for additional sealants or adhesives, cutting costs for manufacturers and installers.

Environmental Durability: Resists moisture, dust, and minor impacts, extending LED equipment lifespan in demanding environments (e.g., outdoor or industrial spaces).

Popular Applications :

Commercial Lighting: Ceiling fixtures, retail store LED panels, and public space lighting.

Automotive Lighting: Headlights, fog lights, and LED signal indicators.

Emergency Lighting: Flashlights and safety fixtures.

Solar Lighting: Solar panel lenses and street luminaires.

Electronic Devices: LED modules for displays, traffic signals, and decorative setups.

Benefits for Manufacturers & Users:

Cost Reduction: Pre-cut tape minimizes waste and streamlines assembly processes.

3M Trusted Warranty: Provides technical confidence, leveraging a globally recognized brand for adhesive quality.

Design Flexibility: Adapts to any lens configuration, including complex curves and angles.

Enhanced Thermal Efficiency: Acts as a soft thermal conductor, facilitating heat dissipation in high-power LED modules.