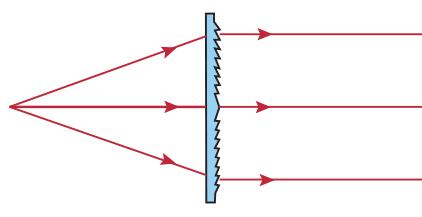

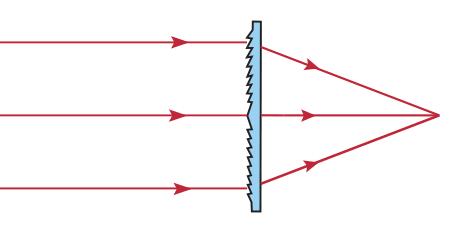

Fresnel lens is used for LED light source to increase light efficiency and brightness. Compared with the same lens and LED light, the focal length and distance are different, and the angle of outgoing light can be set arbitrarily. Single light or multiple array LEDs The lights can be designed according to the needs. The size of the lens can be designed according to customer needs, and the light output angle can be adjusted to reduce the cost of mold opening. Precise machine tool processing realizes the accurate transmission of light. Features: Fresnel lens has the advantages of ultra-thin structure, super large size, ultra-light weight, arbitrary shape cutting, excellent light transmittance, low price, light and easy to carry, etc. It has more advantages than traditional convex lenses, and its weight is less than Convex lens, suitable for many occasions. Widely used in: LED floodlights, colorful floodlights, lighting, landscape lights, signal lights, wall washers and other lamps.

Flexible size allows cutting of Fresnel lenses for COB architectural and stage lighting compatible with all LED types and sizes.

Datasheet Of Fresnel Lenses

(Focal length is constant,the size can be from large to small,so many specifications can be derived)

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F1506 | 15 | 6 | 0.4 | Round |

| 2 | HX-F2412 | 24 | 12 | 0.3 | Round |

| 3 | HX-F3020 | 30 | 20 | 0.1 | Round |

| 4 | HX-F4528 | 45 | 28 | 0.2 | Round |

| 5 | HX-F6038 | 60 | 38 | 0.2 | Round |

| 6 | HX-F6039 | 60 | 39 | 0.2 | Round |

| 7 | HX-F060400 | 60 | 400 | 0.2 | Round |

| 8 | HX-F063135 | 63 | 135 | 0.5 | Round |

| 9 | HX-F70278 | 70 | 27.8 | 0.5 | Round |

| 10 | HX-F7083 | 70 | 83 | 0.3 | Round |

| 11 | HX-F7226 | 72 | 26 | 0.3 | Round |

| 12 | HX-F8043 | 80 | 43 | 0.3 | Round |

| 13 | HX-F8570 | 85 | 70 | 0.3 | Round |

| 14 | HX-F9029 | 90 | 29 | 0.3 | Round |

| 15 | HX-F9062 | 90 | 62 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F100040 | 100 | 40 | 0.3 | Round |

| 2 | HX-F100050 | 100 | 50 | 0.3 | Round |

| 3 | HX-F100060 | 100 | 60 | 0.3 | Round |

| 4 | HX-F100080 | 100 | 80 | 0.3 | Round |

| 5 | HX-F100090 | 100 | 90 | 0.3 | Round |

| 6 | HX-F100095 | 100 | 95 | 0.5 | Round |

| 7 | HX-F100100 | 100 | 100 | 0.3 | Round |

| 8 | HX-F100120 | 100 | 120 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F120063 | 120 | 63 | 0.3 | Round |

| 2 | HX-F120090 | 120 | 90 | 0.5 | Round |

| 3 | HX-F120130 | 120 | 130 | 0.3 | Round |

| 4 | HX-F120135 | 120 | 135 | 0.3 | Round |

| 5 | HX-F120140 | 120 | 140 | 0.3 | Round |

| 6 | HX-F120148 | 120 | 148 | 0.3 | Round |

| 7 | HX-F120185 | 120 | 185 | 0.3 | Round |

| 8 | HX-F120210 | 120 | 210 | 0.3 | Round |

| 9 | HX-F120220 | 120 | 220 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F150090 | 150 | 90 | 0.5 | Round |

| 2 | HX-F150130 | 150 | 130 | 0.3 | Round |

| 3 | HX-F150140 | 150 | 140 | 0.3 | Round |

| 4 | HX-F150148 | 150 | 148 | 0.3 | Round |

| 5 | HX-F150185 | 150 | 185 | 0.3 | Round |

| 6 | HX-F150200 | 150 | 200 | 0.3 | Round |

| 7 | HX-F150210 | 150 | 210 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F160140 | 160 | 140 | 0.3 | Round |

| 2 | HX-F160148 | 160 | 148 | 0.3 | Round |

| 3 | HX-F160175 | 160 | 175 | 0.3 | Round |

| 4 | HX-F160185 | 160 | 185 | 0.3 | Round |

| 5 | HX-F160200 | 160 | 200 | 0.3 | Round |

| 6 | HX-F160210 | 160 | 210 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F180080 | 180 | 80 | 0.3 | Round |

| 2 | HX-F180148 | 180 | 148 | 0.3 | Round |

| 3 | HX-F180200 | 180 | 200 | 0.3 | Round |

| 4 | HX-F180260 | 180 | 260 | 0.3 | Round |

| 5 | HX-F180326 | 180 | 326 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F200080 | 200 | 80 | 0.5 | Round |

| 2 | HX-F200090 | 200 | 90 | 0.5 | Round |

| 3 | HX-F200100 | 200 | 100 | 0.5 | Round |

| 4 | HX-F200120 | 200 | 120 | 0.3 | Round |

| 5 | HX-F200135 | 200 | 135 | 0.5 | Round |

| 6 | HX-F200140 | 200 | 140 | 0.3 | Round |

| 7 | HX-F200148 | 200 | 148 | 0.3 | Round |

| 8 | HX-F200160 | 200 | 160 | 0.3 | Round |

| 9 | HX-F200185 | 200 | 185 | 0.5 | Round |

| 10 | HX-F200200 | 200 | 200 | 0.3 | Round |

| 11 | HX-F200210 | 200 | 210 | 0.5 | Round |

| 12 | HX-F200220 | 200 | 220 | 0.5 | Round |

| 13 | HX-F200230 | 200 | 230 | 0.5 | Round |

| 14 | HX-F200240 | 200 | 240 | 0.5 | Round |

| 15 | HX-F200250 | 200 | 250 | 0.3 | Round |

| 16 | HX-F200260 | 200 | 260 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F230090 | 230 | 90 | 0.5 | Round |

| 2 | HX-F230100 | 230 | 100 | 0.5 | Round |

| 3 | HX-F230135 | 230 | 135 | 0.5 | Round |

| 4 | HX-F230170 | 230 | 170 | 0.3 | Round |

| 5 | HX-F230185 | 230 | 185 | 0.5 | Round |

| 6 | HX-F230200 | 230 | 200 | 0.5 | Round |

| 7 | HX-F230210 | 230 | 210 | 0.5 | Round |

| 8 | HX-F230220 | 230 | 220 | 0.5 | Round |

| 9 | HX-F230230 | 230 | 230 | 0.5 | Round |

| 10 | HX-F230240 | 230 | 240 | 0.2 | Round |

| 11 | HX-F230250 | 230 | 250 | 0.3 | Round |

| 12 | HX-F230260 | 230 | 260 | 0.3 | Round |

| 13 | HX-F230315 | 230 | 315 | 0.5 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F250090 | 250 | 90 | 0.5 | Round |

| 2 | HX-F250100 | 250 | 100 | 0.5 | Round |

| 3 | HX-F250135 | 250 | 135 | 0.5 | Round |

| 4 | HX-F250140 | 250 | 140 | 0.3 | Round |

| 5 | HX-F250160 | 250 | 160 | 0.3 | Round |

| 6 | HX-F250170 | 250 | 170 | 0.3 | Round |

| 7 | HX-F250185 | 250 | 185 | 0.5 | Round |

| 8 | HX-F250200 | 250 | 200 | 0.5 | Round |

| 9 | HX-F250210 | 250 | 210 | 0.5 | Round |

| 10 | HX-F250220 | 250 | 220 | 0.5 | Round |

| 11 | HX-F250230 | 250 | 230 | 0.5 | Round |

| 12 | HX-F250240 | 250 | 240 | 0.5 | Round |

| 13 | HX-F250250 | 250 | 250 | 0.5 | Round |

| 14 | HX-F250290 | 250 | 290 | 0.5 | Round |

| 15 | HX-F250300 | 250 | 300 | 0.3 | Round |

| 16 | HX-F250315 | 250 | 315 | 0.3 | Round |

| 17 | HX-F250326 | 250 | 326 | 0.5 | Round |

| 18 | HX-F250356 | 250 | 356 | 0.5 | Round |

| 19 | HX-F250400 | 250 | 400 | 0.3 | Round |

| 20 | HX-F250450 | 250 | 450 | 0.3 | Round |

| 21 | HX-F250500 | 250 | 500 | 0.3 | Round |

| 22 | HX-F250510 | 250 | 510 | 0.5 | Round |

| 23 | HX-F250600 | 250 | 600 | 0.5 | Round |

| 24 | HX-F250680 | 250 | 680 | 0.5 | Round |

| 25 | HX-F250900 | 250 | 900 | 0.3 | Round |

| 26 | HX-F2501000 | 250 | 1000 | 0.3 | Round |

| 27 | HX-F2502000 | 250 | 2000 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F300120 | 300 | 120 | 0.3 | Round |

| 2 | HX-F300200 | 300 | 200 | 0.5 | Round |

| 3 | HX-F300210 | 300 | 210 | 0.5 | Round |

| 4 | HX-F300220 | 300 | 220 | 0.5 | Round |

| 5 | HX-F300260 | 300 | 260 | 0.3 | Round |

| 6 | HX-F300290 | 300 | 290 | 0.5 | Round |

| 7 | HX-F300326 | 300 | 326 | 0.3 | Round |

| 8 | HX-F300356 | 300 | 356 | 0.5 | Round |

| 9 | HX-F300400 | 300 | 400 | 0.3 | Round |

| 10 | HX-F300510 | 300 | 510 | 0.5 | Round |

| 11 | HX-F300600 | 300 | 600 | 0.3 | Round |

| 12 | HX-F300680 | 300 | 680 | 0.5 | Round |

| 13 | HX-F300900 | 300 | 900 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F350220 | 350 | 220 | 0.3 | Round |

| 2 | HX-F350240 | 350 | 240 | 0.3 | Round |

| 3 | HX-F350300 | 350 | 300 | 0.3 | Round |

| 4 | HX-F350450 | 350 | 450 | 0.3 | Round |

| 5 | HX-F350700 | 350 | 700 | 0.5 | Round |

| 6 | HX-F350900 | 350 | 900 | 0.3 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F400220 | 400 | 220 | 0.5 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F500300 | 500 | 300 | 0.5 | Round |

| 2 | HX-F500540 | 500 | 540 | 0.5 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F600300 | 600 | 300 | 0.5 | Round |

| 2 | HX-F600700 | 600 | 700 | 0.5 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F900700 | 900 | 700 | 0.5 | Round |

| 2 | HX-F900890 | 900 | 890 | 0.5 | Round |

| No. | Model | Diameter (mm) | Focal length (mm) | Groove Pitch (mm) | Shape |

| 1 | HX-F11001000 | 1100 | 1000 | 0.5 | Round |

| 2 | HX-F11001300 | 1100 | 1300 | 0.5 | Round |